Many industrial operations could benefit from automating a wide range of processes, but it isn’t always easy to identify which areas would be most suitable for automation. The robotics market has been flooded with new solutions in recent years, often making it difficult for buyers to determine which solution would be best for their operational needs. As a robotic integrator, we can help to alleviate the complexity of these choices.

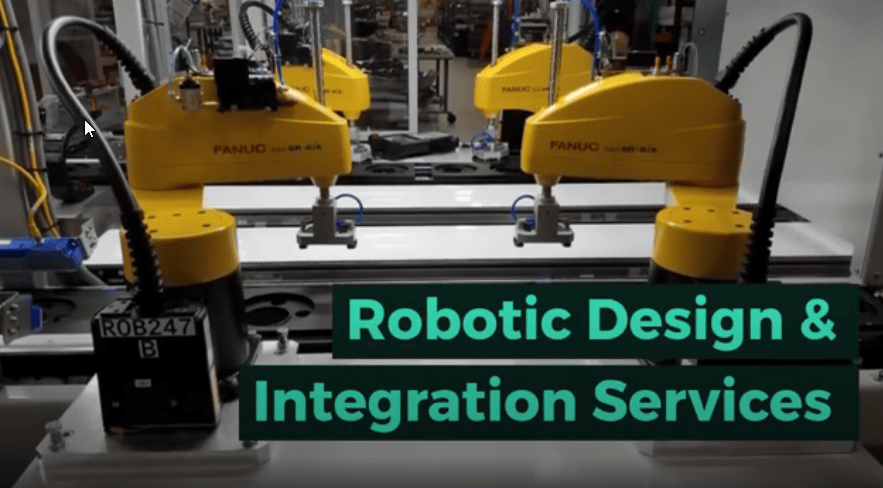

Custom robotic system design and integration services from Big Sky Engineering provide you with an innovative solution that delivers high productivity on your assembly, manufacturing, and packaging lines. We carefully assess your needs before beginning our custom design to ensure that we provide a flexible automation system tailored to the specific requirements of your application.

We will assess your robotics system needs, develop a comprehensive plan for automation, then put that plan into motion. Robotic solutions help you to reduce labor expenses while improving safety and reliability within your facilities. Through robotic solutions, simple repetitive tasks and jobs that are traditionally dangerous to humans may instead be conducted by industrial-grade robots.

Robotic systems offer improved accuracy, higher quality, superior repeatability, and increased versatility. Tooling can be swapped to support multiple products in a variety of applications and systems can be reprogrammed to handle a range of functions.

Examples of applications include:

- Heavy payload

- Line tracking

- Part placement

- Pick-and-place

- Pick-and-pack

- Stacking

- Palletizing

- Machine loading/unloading

- Trimming

- Routing

- Deburring

Robot Packaging Machines

Robotic integration offers a myriad of benefits for packaging operations. Laborious manual tasks such as palletization can be relegated to heavy duty machinery, mitigating the physical risks posed to employees who conduct repetitive tasks. Many related processes can be seamlessly automated, including:

- Case packing

- Pallet dispensing

- Palletizing

- Depalletizing

Through the use of modern technology such as 3D modeling and simulations, it’s possible to create customized robotic cells tailored to the specific needs of any organization. End-of-arm tooling designed by application and advanced integrated controls can provide user-friendly automation solutions in nearly any industrial facility.

Working with Big Sky Engineering allows packaging organizations to improve the efficiency of their operations while reducing long-term costs. Our staff is dedicated to designing innovative solutions to meet all of your packaging needs. Whether you need to automate a single process or re-engineer your whole facility, we possess the capabilities to help you achieve your automation goals.

More than anything, robotic packaging automation offers organizations the freedom to remove skilled workers from jobs that involve repetitive, unskilled, and/or unfulfilling tasks. These tasks are critical to meeting production needs, but manpower and employee knowledge are often wasted on them. Implementing robotic packaging solutions with Big Sky allows:

- Maximum performance with minimal staff

- Improved safety on dangerous or ergonomically stressful tasks

- Flawless high-speed operation

- Reduced material waste/costs

- Increased production capacity

The Big Sky Difference

All our solutions feature custom-engineered controls packages that are intuitive for the end user, yet robust enough to handle exceptions. Our systems operate in conditions ranging from the most pristine cleanrooms to the harshest industrial environments, and we design all systems with the utmost safety in mind.

As an authorized integrator for FANUC products, we design systems with 4, 5, and 6 axis robots with reach capacity from 500-4000 mm and payload capacity from 5-120 kg. End effector choices are numerous and include:

- Gripper assemblies

- Vacuum pickoffs

- Automatic tool changers

- Pneumatic

- Multi-functional

- Multi-headed tools

Our knowledgeable, friendly staff are ready to provide you with customized solutions that meet your individual application needs. If you’re interested in learning more about Big Sky’s robotic design and systems integration services, contact us today or request a quote.