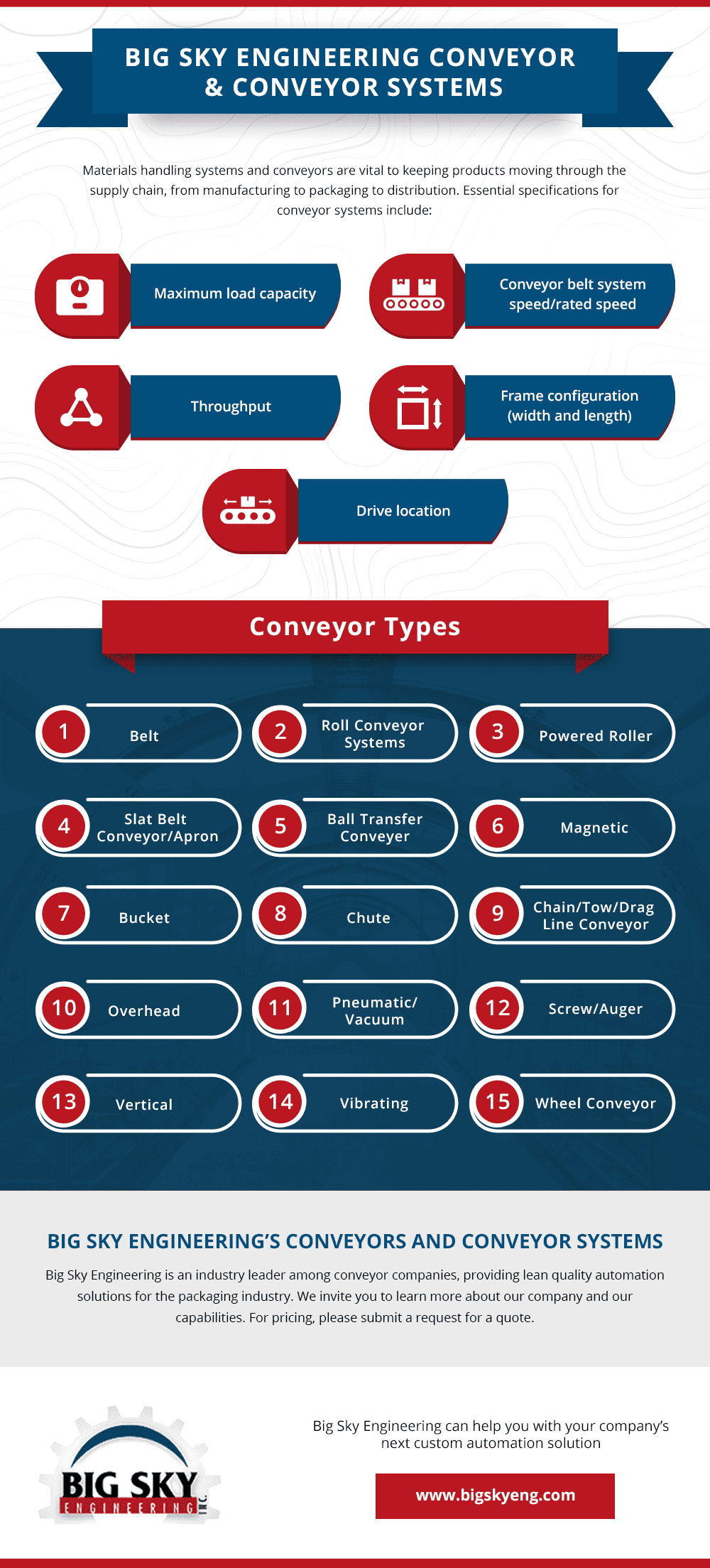

Materials handling systems and conveyors are vital to keeping products moving through the supply chain, from manufacturing to packaging to distribution. Essential specifications for conveyor systems include:

- Maximum load capacity

- Conveyor belt system speed/rated speed

- Throughput

- Frame configuration (width and length)

- Drive location

CONVEYOR TYPES

There are several types of material-handling conveyor systems. Depending on the process and the materials being moved, some varieties may be more beneficial for certain applications than others.

Belt

A belt conveyor is a versatile yet simple design consisting of a fabric, plastic, or rubber belt stretched over two or more pulleys that create an endless loop. A variety of products and materials can be moved uphill or around curves, and the speed can be variable, constant, or stopped and started.

ROLL CONVEYOR SYSTEMS

Roll conveyors move products down a system of parallel rollers mounted in frames via gravity. They are one of the most affordable options and can be combined with other material handling systems with the help of conveyor system integrators. They also come in a wide variety of roll sizes and frame types.

POWERED ROLLER

With this type of conveyor, some or all of the rollers are powered to move the product down the line. Usually, one in nine rollers on the frame is powered by an internal motor and linked to the other non-powered rollers with O-rings. These are ideal for lightweight, flat-bottomed materials.

SLAT BELT CONVEYOR/APRON

This heavy-duty, long-lasting chain-driven conveyor comprises non-overlapping slats or plates made of steel mounted on roller chains. It offers superior stability for even irregular-shaped items and can transport heavy, hot, or dangerous items.

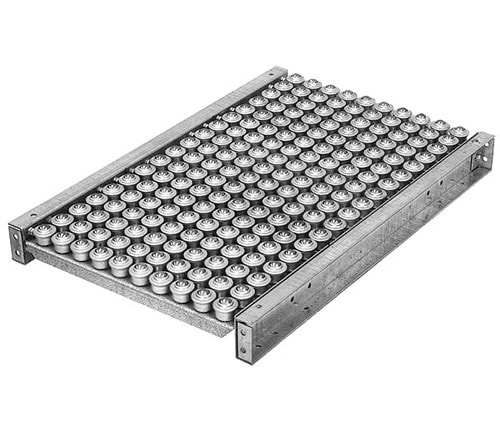

BALL TRANSFER CONVEYOR

With ball transfer conveyors, there are mounted casters between frames, which allow products to move in any direction. It appears often in sorting systems and relies on external forces to move the product.

MAGNETIC

Magnetic conveyors are created by placing magnets in the bed of a standard conveyor to hold iron-containing parts so they can be moved securely throughout elevation changes. They can be beltless and used upside down. They are ideal for holding parts for precision assembly.

BUCKET

Bucket conveyors allow bulk materials to be moved securely from one point to another. Each trough is self-leveling to prevent spillage across elevations. They can be used horizontally, inclined, or vertically. The materials in a bucket conveyor can be transported and deposited without packaging or sorting.

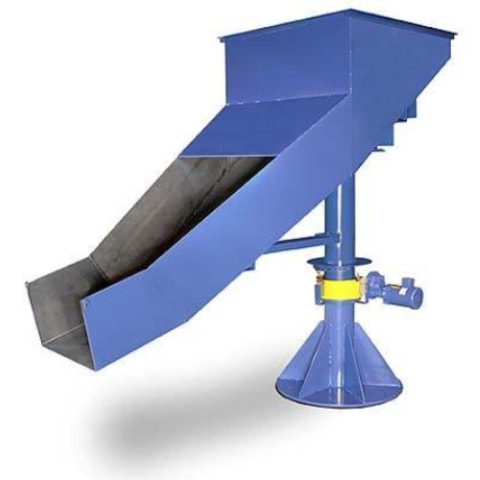

CHUTE

Chute conveyors can be straight or curved and use gravity to load aggregate materials on belt conveyors. They can move everything from powders and grains to ore, and use a low coefficient of dynamic friction.

CHAIN/TOW/DRAG LINE CONVEYOR

These durable conveyors can be used for heavy parts and move industrial containers, racks, pallets, and any products with a sturdy surface on a continuous chain. They are easy to install and require minimal maintenance.

OVERHEAD

This single rail system uses trolleys or carriers moved by chains or cables to distribute load handling across work areas. They leverage the full capacity of a facility by utilizing overhead space. Overhead conveyors are very safe with low operating costs.

PNEUMATIC/VACUUM

These closed-wall conveyor systems use air or vacuum pressure to move products to and from silos, railcars, and more. They can be easily integrated into existing production systems, have a wide capacity range, and evacuate completely, which minimizes cross-contamination. They are very reliable and easy to maintain as well.

SCREW/AUGER

Low profile screw/auger conveyors use helical screw elements that rotate around a central shaft to move chips, sludge, and scrap materials. They can be used in places with limited space and can either split or merge traffic lanes. They can also be perforated to drain liquids.

VERTICAL

These conveyors move products vertically for loading or inventory storage. They can be used for lifting luggage, boxes, packages, cartons, containers, pallets, and more. Vertical conveyors are space-saving, high-performing, quiet, and cost-effective options.

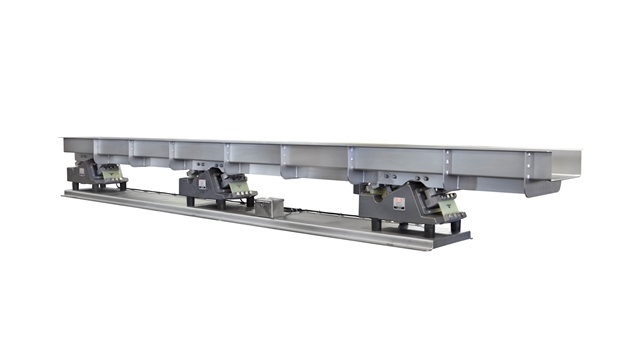

VIBRATING

With vibrating conveyors, a smooth trough, tube, or tabletop is vibrated to impart static and dynamic forces on bulk materials to move them up or down a pathway. They can be used for horizontal or shallow inclines and are appropriate for most aggregates, from powders to solids to non-uniform materials

WHEEL CONVEYOR

These conveyors are an alternative to non-powered roller conveyors and are mounted between tracks to move wide products with clearance between rails. Wheel conveyors use less steel than other conveyors.