Made up of workstations joined by transfer systems to move products and control systems to process the needed coding instructions, automated production lines involve varying levels of technology from robotics and mechanical equipment to specific systems and programs. Human intervention is either unnecessary or carried out in a supervisory capacity.

Research from the World Economic Forum shows that, from January to September of 2021, US companies purchased more robots than ever, due in large part to the coronavirus pandemic causing problems with finding staff. However, you do not need a pandemic or labor shortages to rationalize the need to upgrade to automated production systems.

There are three basic types of production line automation: fixed, programmable, and flexible. Each has its own set of benefits, and which one is best for you will depend on your existing processes and products. In general, however, automating your production lines:

There are three basic types of production line automation: fixed, programmable, and flexible. Each has its own set of benefits, and which one is best for you will depend on your existing processes and products. In general, however, automating your production lines:

- Results in better accuracy

- Allows less human error

- Lowers overhead costs

- Lessens downtime

- Creates a safer workplace

Fixed Automation

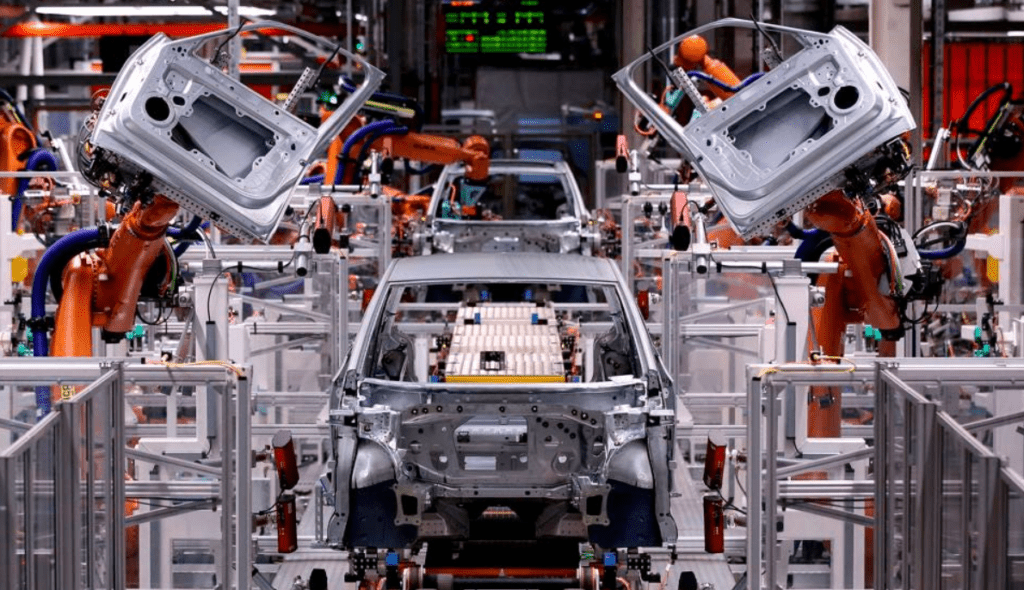

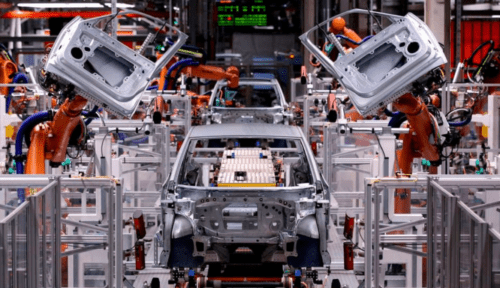

Also known as hard automation, fixed automation uses fixed machinery to complete whatever specific task it is created to do. A parallel is the groundbreaking McDonald’s fast-food model of having one employee do one simple task repeatedly. A manufacturing example of fixed automation would be the automated assembly lines used in the production of vehicles or material handling at food plants.

Fixed automation can require more of an initial investment and does not allow for much flexibility in changing what products or designs the machines generate, but as a result, it typically leads to higher production volumes paired with lower unit costs.

Programmable Automation

For needs that are less repetitive, programmable automation is ideal because it is capable of changes to product design or the order of manufacturing steps, allowing for greater functionality with one system. The machinery is set up with a coded procedure that it then follows in sequence for product creation. The program can be altered and the system will read the new coding, thereby granting the capability for the production line’s use for alternate items.

As a result, another benefit with programmable automation is the option for manufacturing in batches, with multiple components coming off of the same automatic production line.

Flexible Automation

Also called soft automation, this type of automation builds on the idea of programmable automation. It also relies on computer programming to adjust machines and their output.

However, flexible automation systems can save production time because you can configure them to create different parts more easily and quickly, with very little transition time needed in between. Again, an added benefit with this system is that the machinery is able to manufacture different parts continuously on the same line.

Automation Your Way

At Big Sky Engineering, we are at the forefront of automation and continue to develop cutting-edge solutions for our clients. Our project management team will work closely with you to identify your unique needs and provide you with the best solution for your production lines. To find out more about how Big Sky can get you started, contact us today or request a quote for your automation solutions.