SITUATION

The purchasing customer expressed the desire to expand its assembly operations for a fastener filling and packaging assembly line. The former antiquated process was slower using manual loading and packaging methods. The customer required the machine to be completely autonomous aside from loading the clamshells and product labels. The machine would require integrated labelers and a filling machine. The filling machine would be adaptable for multiple screw types.

OPPORTUNITY & IMPLEMENTATION

The proposed and final stations include:

Denester- The Denester station picks the thermoforms from the in-feed magazine. The thermoforms are placed in the machine’s indexer and places the cap parts into the rotating index dial.

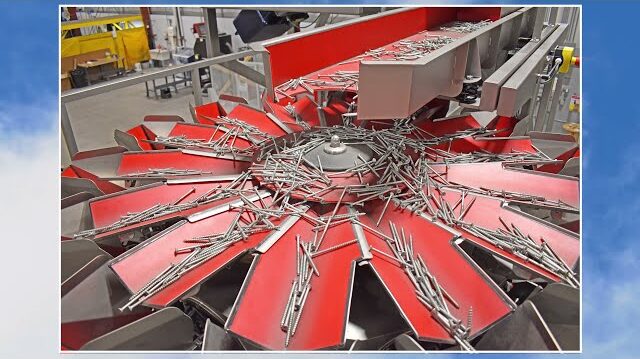

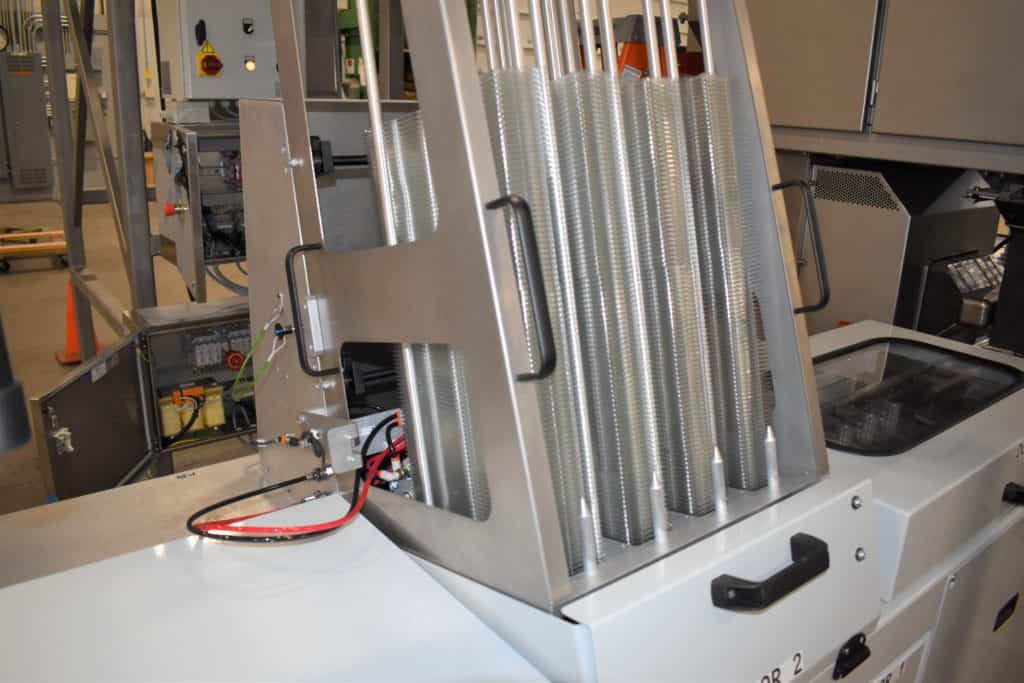

Filling Station- The integrated product filler places the fastener parts into the plastic thermoforms.

Closing Station– The closing station closes the thermoform lids ensuring all parts are securely sealed in the thermoform.

Unload Station- The unload station transfers the packages from the indexer to the labeler conveyor belt station.

Labeler Station- The bottom and nip conveyors keep the package in place while the product labels are being applied.

Unload Transfer- The packages enter the second unload station, the packages are orientated on the packaging in-feed conveyor.

Carton Infeed- Un-erected cartons are placed in the carton in-feed conveyor. The conveyor automatically indexes to provide the carton erector station with cartons consistently.

Carton Erector- The carton erector picks the carton from the in-feed conveyor. Pneumatic components erect the carton and ensure the tabs are properly inserted.

Robot Pick and Place– The robot picks the packages from the in-feed nest and places them into the erected carton.

DESIGN FEATURES & SPECIFICATIONS

- Fanuc Robot Cell

- Unload and Reject stations with bins under the machine table.

- Class 3 guard enclosure.

- Output: 80 PPM.

- Stack Light Indicators display the current machine state.

- Allen-Bradley 10” PanelView HMI

- The machine HMI uses customary pictures & buttons for control overrides. All machine sequences can be

operated in manual mode on the HMI. Current cycle times are displayed on the HMI.

Approximate Combined Machine Dimensions: 30”L x 38’W x 20’H

Filling & Labeling Power Requirements: 480VAC, 3 Phase, 30A

Carton Packaging Requirements: 480VAC, 3 Phase, 30A

Pneumatic Requirements: 80PSI – 5 SCFM